Hi all,

Hope you all had a jolly good Christmas. Mine was good, not exciting but good not least because the eating was spot on. My wife does a delicious turkey dinner and the best trifle ever to find itself on a spoon.

I know we say it every year, but this year the television hit an all time low, in fact, it was nothing but repeats and rubbish. I tried to keep an open mind but the quality of some of the new shows was grim.

Ah well, who wants to sit in front of the box anyhow when so many crafts are waiting to be tried. I told you before Xmas that I was working on a automata and I have managed to cut out all of the pieces and start the assembly work.

So far everything has gone to plan even if progress is slower than expected. I should be able to show you the finished article in my next post and give you a report on how enjoyable it was project wise.

The reason the Automata didn't get finished in time for Christmas was the effort I had to put into making the two surprise boxes that I was making my wife for Christmas presents.

The first box was was cut form a block of maple and I used my scroll saw to cut our a heart shape in the middle. The base and the lid were both cut from a panel of 6mm thick walnut. Into the lid I cut out a shape of a rose and then inlaid a piece of 6mm Baltic birch to give it a light enough background for the rose pyrography. It was finished with three layers of varnish to give it a high gloss finish.

I was very pleased with the way it came out especially the pyrography. My wife was also pleased when she opened her present and she was impressed with the way I had used flocking to give the inside of the heart a nice feel.

Because the inlaid wood is solid and the same thickness as the lid it is seen from the inside and outside of the box, so I had to repeat the pyrography on the inside of the lid. Obviously it comes out upside down but it gives a great effect.

My efforts to get a really nice gloss finish are finally paying off. If I look at the stuff I'm producing now it is much better and I would put it down to sanding. I used to just get some fine sand paper give it a rub and hope for the best and reap indifferent results. Now however, I am more disciplined, I start with 180 grit and then work my way through until I get to 400 grit which gives me a really good finish.

The other box I made for my wife centered around a hare that I had cut out of a piece of mahogany. This would form the lid if it came out okay.

It was my intention to fill the hare aperture with polymer clay and mould it into the shape of a hare, so that one half of it would be raised on the top of the box. The nearest thing I'd ever done to that type of moulding was with some plastercine when I was about 8 years old, so I decided to see how the lid progressed before I committed myself to making the actual box.

I will show you the finished article in my next post because I want to tell you all about it. I've had a few disasters when making wooden items but not nearly as many as dogged that box during the lead up to Christmas. If I don't catch you before let me wish you all the best for the new year and hope that it is an healthy one.

Saturday, 27 December 2014

Wednesday, 17 December 2014

Lacquered Box

Hi All,

It has been slow slow progress on the pyrography and scroll sawing projects this week. I said in my last post that I was going to have a go at an automata but other than cutting a few pieces that hasn't gone very far either.

The main problem is that I have been suffering from a really bad cold. I'm not one to exaggerate the effects of a cold and never had time off work when suffering from one. However, the one that is currently giving me some gyp is wicked and I think I would have a had to have a week off.

The other problem I have at the moment is my workshop, it's colder than penguin's winkle. It used to be the garage, so the walls are only one brick thick and it is impossible to get it proper warm. I've had electric fire on but after a while the cold seeps out of the concrete floor and up my legs. Within an hour I'm walking like Douglas Bader.

Having said all that, I did manage to finish a box that I was making as part of an experiment. Getting a good high gloss finish is something that I really desire and I'm trying to find out how it is done. I've tried varnish, which is okay, but it doesn't give me the finish I'm looking for and it isn't fully compatible with polymer clay,

So, I have finished the top of a box using lacquer and the results are looking favourable.

The box above was given 4 coats of lacquer and now needs a week to fully harden before I take it a bit further. Apparently, I have to give it a rub down with some 1200 grit wet and dry and then buff it up to a glossy shine with car polish.

Applying a coat of lacquer is different from working with varnish because lacquer goes off almost immediately. If you wipe your brush over piece that you have already done you can get into a right mess. In my next post I hope to show you the box again and you can judge it the finish is better and who knows, I might get the automata finished.

It has been slow slow progress on the pyrography and scroll sawing projects this week. I said in my last post that I was going to have a go at an automata but other than cutting a few pieces that hasn't gone very far either.

The main problem is that I have been suffering from a really bad cold. I'm not one to exaggerate the effects of a cold and never had time off work when suffering from one. However, the one that is currently giving me some gyp is wicked and I think I would have a had to have a week off.

The other problem I have at the moment is my workshop, it's colder than penguin's winkle. It used to be the garage, so the walls are only one brick thick and it is impossible to get it proper warm. I've had electric fire on but after a while the cold seeps out of the concrete floor and up my legs. Within an hour I'm walking like Douglas Bader.

Having said all that, I did manage to finish a box that I was making as part of an experiment. Getting a good high gloss finish is something that I really desire and I'm trying to find out how it is done. I've tried varnish, which is okay, but it doesn't give me the finish I'm looking for and it isn't fully compatible with polymer clay,

So, I have finished the top of a box using lacquer and the results are looking favourable.

The box above was given 4 coats of lacquer and now needs a week to fully harden before I take it a bit further. Apparently, I have to give it a rub down with some 1200 grit wet and dry and then buff it up to a glossy shine with car polish.

Applying a coat of lacquer is different from working with varnish because lacquer goes off almost immediately. If you wipe your brush over piece that you have already done you can get into a right mess. In my next post I hope to show you the box again and you can judge it the finish is better and who knows, I might get the automata finished.

Tuesday, 9 December 2014

Automata

Hi all,

In my last post I said I was going to try my hand at doing a bit of automata. For those who aren't familiar with the term here is a simple explanation. If you are anywhere as near as old as me you will remember wind up toys, well automata are like wind up toys that can be made from wood.

However, instead of having a clockwork mechanism they are usually powered by a hand turned crank, which activates a number of camshafts and gears that bring animation to the subject.

I was going to have a go at one where a man plays a piano, but decided to do that next because it also needs a musical movement. So,for my first automata I'm going to keep it simple and do one where a cat is trying to catch a mouse. I got the plans free off the Internet and I hope it will be a bit of fun trying to make it. That may be especially true for me because the plans are in German.

As you can see there will be a lot of cutting out to be done but it should be a laugh when it's finished. Perhaps I'm having a late mid-life crisis, other men by a motor bike and ride route 66 but I'm going into toy making. Contentment is a wonderful thing, if ever you see it passing by, get a rope on it and tie it to your bed post.

If you remember from my last post, my wife said she'd gone off my wooden vases. Well that state of affairs that didn't last long. She wanted another for a Christmas present so I just gave her one of my special smiles and obliged.

I have also started a new box in a heart shape. It is cut from Maple and will have a walnut bottom and lid.

The lid is going to have a rose inlaid into it using two woods, Baltic birch plywood and mahogany. When the inlay is complete I will do the rose with my pyrography iron.

It should be finished in a few days and I will let you have a look at it in my next post along with any progress on the automata. Over the next day or two I will be helping my wife with the Christmas deccies so I don't suppose I will get much time for wood working. At least doing some decorations will be warm, at the moment my workshop is as cold as an Eskimo's pantry.

In my last post I said I was going to try my hand at doing a bit of automata. For those who aren't familiar with the term here is a simple explanation. If you are anywhere as near as old as me you will remember wind up toys, well automata are like wind up toys that can be made from wood.

However, instead of having a clockwork mechanism they are usually powered by a hand turned crank, which activates a number of camshafts and gears that bring animation to the subject.

I was going to have a go at one where a man plays a piano, but decided to do that next because it also needs a musical movement. So,for my first automata I'm going to keep it simple and do one where a cat is trying to catch a mouse. I got the plans free off the Internet and I hope it will be a bit of fun trying to make it. That may be especially true for me because the plans are in German.

As you can see there will be a lot of cutting out to be done but it should be a laugh when it's finished. Perhaps I'm having a late mid-life crisis, other men by a motor bike and ride route 66 but I'm going into toy making. Contentment is a wonderful thing, if ever you see it passing by, get a rope on it and tie it to your bed post.

If you remember from my last post, my wife said she'd gone off my wooden vases. Well that state of affairs that didn't last long. She wanted another for a Christmas present so I just gave her one of my special smiles and obliged.

I have also started a new box in a heart shape. It is cut from Maple and will have a walnut bottom and lid.

The lid is going to have a rose inlaid into it using two woods, Baltic birch plywood and mahogany. When the inlay is complete I will do the rose with my pyrography iron.

It should be finished in a few days and I will let you have a look at it in my next post along with any progress on the automata. Over the next day or two I will be helping my wife with the Christmas deccies so I don't suppose I will get much time for wood working. At least doing some decorations will be warm, at the moment my workshop is as cold as an Eskimo's pantry.

Monday, 1 December 2014

Tulips

Hi All,

Following on from my success with the inlaid poppies, I decided to make my wife another vase for her to put her clay flowers in. This time I would make a vase using the same woods; pine and mahogany for the vase and 6mm birch plywood for the inlay.

I had a bit of trouble with the scroll saw work on this one, and to be honest, I still can't get my head around what went wrong. Let me explain. To do an inlay, I tape two pieces of wood together and then cut out the design, once done, the inlay piece fits neatly into the hole on the other piece of wood. That's the theory, but in reality it isn't that simple because the blade of the saw removes some wood and therefore, if you just do a straight cut, the inlay fits like a sausage in shirt sleeve.

To get around the issue, the cut is made at a angle that is appropriate to the thickness of the wood and you then get a nice snug fit. Having said all that, I'm having great difficulty in understanding which bit fits into which bit and on my first attempt at doing the tulips I got it wrong. The plywood inlay fell straight through the mahogany without touching the sides, so I had to glue the original pieces back in. I did that and after using a bit of pyrography to disguise the problem it didn't look too bad.

In fact, it looked nice enough, but only good enough for the rear of the vase because I wanted an inlay on the front. When I did the front again, I went completely opposite to the way I thought it should be done and it came out perfect.

I think the pyrography really sets it off a treat.

My wife liked the finished vase, but there was a problem. She decided that wooden vases bring attention to the fact that her clay flowers aren't actually real, so she doesn't want anymore. In fact, she stuck the Icelandic poppies she'd just finished into a jug from a charity shop.

Ha well, at least I can get on with some of my own stuff now. I'm thinking of having a go at a bit of Automata, I'll let you know if it comes to anything in my next post.

By the way, if you would like to see some more of my wife's flowers here is a Link. She would be pleased with any comments about her work.

Following on from my success with the inlaid poppies, I decided to make my wife another vase for her to put her clay flowers in. This time I would make a vase using the same woods; pine and mahogany for the vase and 6mm birch plywood for the inlay.

I had a bit of trouble with the scroll saw work on this one, and to be honest, I still can't get my head around what went wrong. Let me explain. To do an inlay, I tape two pieces of wood together and then cut out the design, once done, the inlay piece fits neatly into the hole on the other piece of wood. That's the theory, but in reality it isn't that simple because the blade of the saw removes some wood and therefore, if you just do a straight cut, the inlay fits like a sausage in shirt sleeve.

To get around the issue, the cut is made at a angle that is appropriate to the thickness of the wood and you then get a nice snug fit. Having said all that, I'm having great difficulty in understanding which bit fits into which bit and on my first attempt at doing the tulips I got it wrong. The plywood inlay fell straight through the mahogany without touching the sides, so I had to glue the original pieces back in. I did that and after using a bit of pyrography to disguise the problem it didn't look too bad.

In fact, it looked nice enough, but only good enough for the rear of the vase because I wanted an inlay on the front. When I did the front again, I went completely opposite to the way I thought it should be done and it came out perfect.

I think the pyrography really sets it off a treat.

My wife liked the finished vase, but there was a problem. She decided that wooden vases bring attention to the fact that her clay flowers aren't actually real, so she doesn't want anymore. In fact, she stuck the Icelandic poppies she'd just finished into a jug from a charity shop.

Ha well, at least I can get on with some of my own stuff now. I'm thinking of having a go at a bit of Automata, I'll let you know if it comes to anything in my next post.

By the way, if you would like to see some more of my wife's flowers here is a Link. She would be pleased with any comments about her work.

Monday, 24 November 2014

Inlaid Poppies

Hi all, after the hard work I put into the ebonized box with the inlaid polymer clay lid, I decided to do something quicker that would allow me enjoy a bit of pyrography at the same time.

I am struggling to keep up with my wife's requirements for wooden vases, especially as we are coming up to Christmas. She has decided to give bunches of her clay flowers to a couple of her friends and she has commissioned me to do the vases. No money is involved, but I find it is always best to keep on the right side of cook.

Here is a the front of the first vase. The vase is made from a piece of pine which, after doing the inlay work shown below, was sandwiched between two pieces of quarter in thick mahogany. The inlay is done from quarter inch thick Baltic Birch ply wood, which I have chosen because it is great for doing pyrography work on.

Cutting out the flowers is an interesting task especially where there are tight turns. Even when using the smallest blade I can buy, sharp turns are very difficult. You can see in the photo above where I have drilled the hole to pass the blade through the wood to cut out the flowers. I like to position the hole on the inside of the tightest bend because that saves me having to do a sharp turn. I just saw my way out of it, go around the flower and back to the hole. The holes at this stage may look like they will stick out like a sore thumb, but they will be disguised in the finished product.

The rest of the cutting went very well and you can see that there aren't any gaps around the edge of the flowers. This is done by sawing with a slight angle on the blade. Most scroll saws allow the user to change the angle of the scroll saw table, but I have an excalibur saw which allows me to change the angle of the saw which makes angle cutting much easier.

If you are going to attempt to do any inlay work I suggest you cut a few test pieces before you try in on your project. The angle needs to be set relative to the thickness of the wood. If you don't have enough angle you inlay will be a sloppy fit. On the other hand if you set the angle too acutely your inlay won't fit in the hole at all.

For this project with quarter inch thick wood I set the angle a gnat's nudger under 2 degrees, so I suggest you use that for a reference point when doing your test cuts.

Anyway, here is the vase once it had been stuck together sanded and had the pyrography work done.

I like it and my wife seems quite pleased too. Notice how the blade entry holes have been disguised with a little saw dust and pyrography.

In fact, she wants the next vase to have tulips on it, so I will probably have that to show you in my next post. Then I'm done with vases and I'm going to have a go at something completely different

I am struggling to keep up with my wife's requirements for wooden vases, especially as we are coming up to Christmas. She has decided to give bunches of her clay flowers to a couple of her friends and she has commissioned me to do the vases. No money is involved, but I find it is always best to keep on the right side of cook.

Here is a the front of the first vase. The vase is made from a piece of pine which, after doing the inlay work shown below, was sandwiched between two pieces of quarter in thick mahogany. The inlay is done from quarter inch thick Baltic Birch ply wood, which I have chosen because it is great for doing pyrography work on.

Cutting out the flowers is an interesting task especially where there are tight turns. Even when using the smallest blade I can buy, sharp turns are very difficult. You can see in the photo above where I have drilled the hole to pass the blade through the wood to cut out the flowers. I like to position the hole on the inside of the tightest bend because that saves me having to do a sharp turn. I just saw my way out of it, go around the flower and back to the hole. The holes at this stage may look like they will stick out like a sore thumb, but they will be disguised in the finished product.

The rest of the cutting went very well and you can see that there aren't any gaps around the edge of the flowers. This is done by sawing with a slight angle on the blade. Most scroll saws allow the user to change the angle of the scroll saw table, but I have an excalibur saw which allows me to change the angle of the saw which makes angle cutting much easier.

If you are going to attempt to do any inlay work I suggest you cut a few test pieces before you try in on your project. The angle needs to be set relative to the thickness of the wood. If you don't have enough angle you inlay will be a sloppy fit. On the other hand if you set the angle too acutely your inlay won't fit in the hole at all.

For this project with quarter inch thick wood I set the angle a gnat's nudger under 2 degrees, so I suggest you use that for a reference point when doing your test cuts.

Anyway, here is the vase once it had been stuck together sanded and had the pyrography work done.

I like it and my wife seems quite pleased too. Notice how the blade entry holes have been disguised with a little saw dust and pyrography.

In fact, she wants the next vase to have tulips on it, so I will probably have that to show you in my next post. Then I'm done with vases and I'm going to have a go at something completely different

Sunday, 16 November 2014

Ebonized Box Finished

Hi all,

I have just finished the ebonized box project. It has taken a long time and it hasn't been one of my best experiences. When the lid came out of the oven burnt it, still wasn't the end end of the problems but I'll tell you about that in a minute.

For those who missed my last post showing the burnt lid here it is again you save you looking back through old posts.

I did try removing the burnt clay with the hope that it might save me the trouble of cutting the wood, again, but a stick of dynamite wouldn't shift it. The thought of going all that sawing again gave me the gyp so I modified the design to make it a bit quicker to cut. The other thing I did differently was to fill the cut with the clay before painting it with the ebonizing solution.

I noticed that on the first version, that I ebonized first, some of the black was coming off onto the clay so it made sense to fill it first. It was a bit tedious painting around the inlay work with the ebonizing solution but it was the best option.

Anyway, without further dalliance here is the finished box. Any comments would be appreciated.

It doesn't quite have the wow factor that the one in my head had before I made it but it is good enough for a first go at ebonizing. I will have another go at something similar but not just yet because the end result did not match the time and effort I put into it. When I found out that I had made another silly error and cut the lid 6mm too small the thing almost went into the wheelie.

I suppose it worked out well in the end and I have a new box for my bed side table. Every night I will deposit my rings, keys and loose change into it, so it will be very useful.

So what for my next project. Well, I have just done a bit of wooden inlaying on a vase, and I will be getting a result much quicker. I am doing a bit of pyrography on it as well and will show you the finished thing in my next post.

By the way, my wife is doing really well with her clay flower making. In fact, she is getting fed up with having nobody to show them to. I set her a blog up a few months ago and I think she is going to start using it. If you are interested in clay flowers or know anybody else who is that way inclined here is the link. http://www.tatpots.blogspot.com I will leave you with a vase full of her latest creations.

I have just finished the ebonized box project. It has taken a long time and it hasn't been one of my best experiences. When the lid came out of the oven burnt it, still wasn't the end end of the problems but I'll tell you about that in a minute.

For those who missed my last post showing the burnt lid here it is again you save you looking back through old posts.

I did try removing the burnt clay with the hope that it might save me the trouble of cutting the wood, again, but a stick of dynamite wouldn't shift it. The thought of going all that sawing again gave me the gyp so I modified the design to make it a bit quicker to cut. The other thing I did differently was to fill the cut with the clay before painting it with the ebonizing solution.

I noticed that on the first version, that I ebonized first, some of the black was coming off onto the clay so it made sense to fill it first. It was a bit tedious painting around the inlay work with the ebonizing solution but it was the best option.

Anyway, without further dalliance here is the finished box. Any comments would be appreciated.

It doesn't quite have the wow factor that the one in my head had before I made it but it is good enough for a first go at ebonizing. I will have another go at something similar but not just yet because the end result did not match the time and effort I put into it. When I found out that I had made another silly error and cut the lid 6mm too small the thing almost went into the wheelie.

I suppose it worked out well in the end and I have a new box for my bed side table. Every night I will deposit my rings, keys and loose change into it, so it will be very useful.

So what for my next project. Well, I have just done a bit of wooden inlaying on a vase, and I will be getting a result much quicker. I am doing a bit of pyrography on it as well and will show you the finished thing in my next post.

By the way, my wife is doing really well with her clay flower making. In fact, she is getting fed up with having nobody to show them to. I set her a blog up a few months ago and I think she is going to start using it. If you are interested in clay flowers or know anybody else who is that way inclined here is the link. http://www.tatpots.blogspot.com I will leave you with a vase full of her latest creations.

Saturday, 8 November 2014

A Disaster

Hi all,

I've just had a disaster, so I thought I'd share it with you. I said I was going to rescue the ebonising project, but it has gone down hill faster than a fridge strapped to a sledge.

I have done a bit of inlaying with polymer clay before; here is a photo of one I did earlier. The pound coin just gives you an idea of the scale.

Anyway, I inlaid a load of polymer clay into the lid of the box I was working on and stuck it it the oven to cure. Thirty minutes later this is what I came back to.

I felt like weeping buckets but being a male I hung onto my tears and went into a sulk for a couple of hours. I over it now and trying to figure out what went wrong.

If I find out I'll let you know in my next post.

I've just had a disaster, so I thought I'd share it with you. I said I was going to rescue the ebonising project, but it has gone down hill faster than a fridge strapped to a sledge.

I have done a bit of inlaying with polymer clay before; here is a photo of one I did earlier. The pound coin just gives you an idea of the scale.

Anyway, I inlaid a load of polymer clay into the lid of the box I was working on and stuck it it the oven to cure. Thirty minutes later this is what I came back to.

I felt like weeping buckets but being a male I hung onto my tears and went into a sulk for a couple of hours. I over it now and trying to figure out what went wrong.

If I find out I'll let you know in my next post.

Thursday, 6 November 2014

Flowers

Hi All,

My wife asked me to make her a small wooden planter for a cyclamen plant that she was making out of clay. So, being a good and dutiful husband, I dashed into my workshop and knocked her one up with my scroll saw from a piece of reclaimed wardrobe. I didn't gain any brownie point though; when I gave it to her she burst out laughing because it was too small. However, it didn't take her long to fill it full of clay flowers of unknown species.

Undaunted, I returned to my workshop and made something that was of a size more in line with her requirements. With this she was very pleased and, as a reward for my efforts she baked me a delicious raspberry jam and butter cream swiss roll.

Here is the planter with the cyclamen.

While I'm winning, I'm going to make her another wooden vase and do a bit of inlay work and pyrography on the front. I will let you have look at it in my next post along with the progress I've made regarding the ebonizing project. It isn't going to plan, in fact its turning into a disaster but I'm hoping to rescue it during the next couple of days.

My wife asked me to make her a small wooden planter for a cyclamen plant that she was making out of clay. So, being a good and dutiful husband, I dashed into my workshop and knocked her one up with my scroll saw from a piece of reclaimed wardrobe. I didn't gain any brownie point though; when I gave it to her she burst out laughing because it was too small. However, it didn't take her long to fill it full of clay flowers of unknown species.

Undaunted, I returned to my workshop and made something that was of a size more in line with her requirements. With this she was very pleased and, as a reward for my efforts she baked me a delicious raspberry jam and butter cream swiss roll.

Here is the planter with the cyclamen.

While I'm winning, I'm going to make her another wooden vase and do a bit of inlay work and pyrography on the front. I will let you have look at it in my next post along with the progress I've made regarding the ebonizing project. It isn't going to plan, in fact its turning into a disaster but I'm hoping to rescue it during the next couple of days.

Tuesday, 4 November 2014

Ebonized

Hi All,

I finished cutting the wood for the ebonizing project from some oak that I got from Hobbies via the Internet. Hobbies is a great shop for those people who make models and that sort of stuff. If you haven't come across them before they are well worth a look.

After cutting out the pieces of wood on my scroll saw, I joined the sides together to form the box and then set about doing the fret work on the lid.

The scroll saw work on the lid was time consuming but extremely therapeutic; a very fine blade and total concentration was required to cut out the fine lines. Then came the moment of truth, I laid the pieces out and then brushed them all over with my ebonizing solution.

For those who may have missed the post with the recipe, here it is again.

Take one Brillo pad and wash out all the soap. (You could just use a wodge of steel wool instead)

Half fill a jar with white wine vinegar.

Drop the Brillo pad into the jar of liquid, put on the lid and give it a bit of a shake.

Important note: Use a drill to make a few holes in the lid of the jar or make holes in it with a hammer and nail. This is to let the volatile gases, that are produced by the mixture, to escape.

Actually, I can't see why they should be bad but better to be safe that sorry and holes are pretty cheap.

I left the solution in the garden shed to brew for a couple of weeks and to be honest I wasn't really expecting brilliant results as I brushed the stuff on. However, I shouldn't have worried because here is a picture of the same parts five minutes after the ebonizing solution was applied.

So there you go, the oak is now as black as a coal miners thumb and ready to be finished. The only bit that didn't come out black was a strip along one edge of the base and another along the lid. It is obviously something to do with the wood rather than the solution because they were cut from the same piece of wood. Anyway the strip that didn't come out black, came out a lovely shade of grey and it gives the wood a bit a character.

The next stage is to glue the base on and then do the inlay work on the lid. I am looking forward to that and, will hopefully, be able to show you the finished article in the near future

I finished cutting the wood for the ebonizing project from some oak that I got from Hobbies via the Internet. Hobbies is a great shop for those people who make models and that sort of stuff. If you haven't come across them before they are well worth a look.

After cutting out the pieces of wood on my scroll saw, I joined the sides together to form the box and then set about doing the fret work on the lid.

The scroll saw work on the lid was time consuming but extremely therapeutic; a very fine blade and total concentration was required to cut out the fine lines. Then came the moment of truth, I laid the pieces out and then brushed them all over with my ebonizing solution.

For those who may have missed the post with the recipe, here it is again.

Take one Brillo pad and wash out all the soap. (You could just use a wodge of steel wool instead)

Half fill a jar with white wine vinegar.

Drop the Brillo pad into the jar of liquid, put on the lid and give it a bit of a shake.

Important note: Use a drill to make a few holes in the lid of the jar or make holes in it with a hammer and nail. This is to let the volatile gases, that are produced by the mixture, to escape.

Actually, I can't see why they should be bad but better to be safe that sorry and holes are pretty cheap.

I left the solution in the garden shed to brew for a couple of weeks and to be honest I wasn't really expecting brilliant results as I brushed the stuff on. However, I shouldn't have worried because here is a picture of the same parts five minutes after the ebonizing solution was applied.

So there you go, the oak is now as black as a coal miners thumb and ready to be finished. The only bit that didn't come out black was a strip along one edge of the base and another along the lid. It is obviously something to do with the wood rather than the solution because they were cut from the same piece of wood. Anyway the strip that didn't come out black, came out a lovely shade of grey and it gives the wood a bit a character.

The next stage is to glue the base on and then do the inlay work on the lid. I am looking forward to that and, will hopefully, be able to show you the finished article in the near future

Tuesday, 28 October 2014

Ebonizing Project

Hi all,

I have made the sides, lid and base for the box that I am going to ebonize, but before I put on the ebonizing solution I wanted to do the scroll saw work on the lid.

I did the design for the inlay which can be seen below.

I think I must have got carried away because it was only when I finished did I realise that I'd made it very fine. Doing the inlay work of filling the leaves, stems and flowers won't be too difficult, but I'm going to have to be very patient when cutting it out on the scroll saw.

In fact, I hit my first snag before I could get started. Cutting the design out will require very fine blades and I didn't have any. Scroll saw blades come in a range of sizes from 2/0, which is 0.010 inches thick, to a size 12r, which is 0.024 inches thick. If you can't get your head around those numbers think in terms of drill sizes. A pilot hole of one 32nd of an inch is all that is needed to pass the smallest blade through.

Anyway, I've been using a lot of medium sized blades lately and hadn't thought about getting some new small blades. Whilst we are talking about blades, there are several different makes to choose from. I use Olson blades mainly because they are easy to order from here they also have a great range of pyrography blanks, plans, rotary tools and lots of other stuff associated with small woodworking projects.

Delivery is usually pretty good, so I'm keeping my fingers crossed that the blades will be here tomorrow and I can then get on with the ebonizing project. Mean while I'm going to make a start on another project which will involve some pyrography work

I have made the sides, lid and base for the box that I am going to ebonize, but before I put on the ebonizing solution I wanted to do the scroll saw work on the lid.

I did the design for the inlay which can be seen below.

I think I must have got carried away because it was only when I finished did I realise that I'd made it very fine. Doing the inlay work of filling the leaves, stems and flowers won't be too difficult, but I'm going to have to be very patient when cutting it out on the scroll saw.

In fact, I hit my first snag before I could get started. Cutting the design out will require very fine blades and I didn't have any. Scroll saw blades come in a range of sizes from 2/0, which is 0.010 inches thick, to a size 12r, which is 0.024 inches thick. If you can't get your head around those numbers think in terms of drill sizes. A pilot hole of one 32nd of an inch is all that is needed to pass the smallest blade through.

Anyway, I've been using a lot of medium sized blades lately and hadn't thought about getting some new small blades. Whilst we are talking about blades, there are several different makes to choose from. I use Olson blades mainly because they are easy to order from here they also have a great range of pyrography blanks, plans, rotary tools and lots of other stuff associated with small woodworking projects.

Delivery is usually pretty good, so I'm keeping my fingers crossed that the blades will be here tomorrow and I can then get on with the ebonizing project. Mean while I'm going to make a start on another project which will involve some pyrography work

Thursday, 23 October 2014

Ebonizing

Hi all,

I have been deprived of crafting time for a long time but that is about to come to and end because my wife can't stand the smell of paint. This means that the decorating is being put on hold till next April when we can have the windows open to let the fumes out.

So, I'm like a dog with 2 bones at the moments and, because I was spoilt for choice and didn't know which project to do first, I have started 3 at the same time.

I will tell you about the others in my next post but first I will share my ebonizing project with you. I have always been keen on the look of pietra dura, which is all about using precious stones to form pictures. They are inlaid into other pieces of stone or sometimes inlaid into wood.

So I have decided to make a box, cut out some flowers on the top with my scroll saw and then inlay them with clay because I can't afford precious stones.

To get a good contrast between the wood and the stones, pietra dura artists commonly used ebony, which is a black wood that can be seen on the keyboard of a piano. Ebony is a very expensive wood so I decided to make my own, Obviously I can't make wood, but according to what I have researched it is possible to ebonize other woods and make them black by painting them with a special solution.

Oak is a good wood because it contains the right natural ingredients to react with the special solution which is made from steel wool and white wine vinegar. No, I'm not making this up and if you manage to stay with me for a few post you can see if it works.

I rinsed the soap out of one of my wife's brillo pads when she wasn't looking and mixed it with some of the white wine vinegar she had lurking at the back of the pantry. I put the pad in an empty marmalade jar poured on the vinegar and, after drilling a few holes in the top to allow obnoxious gases to escape, I took it down to my shed to let it ferment. Here it is after two weeks brewing.

Tomorrow, I'm going to begin cutting the wood for the box and then I can see if this magic solution works, If it doesn't, I suppose there is always black paint.

I have been deprived of crafting time for a long time but that is about to come to and end because my wife can't stand the smell of paint. This means that the decorating is being put on hold till next April when we can have the windows open to let the fumes out.

So, I'm like a dog with 2 bones at the moments and, because I was spoilt for choice and didn't know which project to do first, I have started 3 at the same time.

I will tell you about the others in my next post but first I will share my ebonizing project with you. I have always been keen on the look of pietra dura, which is all about using precious stones to form pictures. They are inlaid into other pieces of stone or sometimes inlaid into wood.

So I have decided to make a box, cut out some flowers on the top with my scroll saw and then inlay them with clay because I can't afford precious stones.

To get a good contrast between the wood and the stones, pietra dura artists commonly used ebony, which is a black wood that can be seen on the keyboard of a piano. Ebony is a very expensive wood so I decided to make my own, Obviously I can't make wood, but according to what I have researched it is possible to ebonize other woods and make them black by painting them with a special solution.

Oak is a good wood because it contains the right natural ingredients to react with the special solution which is made from steel wool and white wine vinegar. No, I'm not making this up and if you manage to stay with me for a few post you can see if it works.

I rinsed the soap out of one of my wife's brillo pads when she wasn't looking and mixed it with some of the white wine vinegar she had lurking at the back of the pantry. I put the pad in an empty marmalade jar poured on the vinegar and, after drilling a few holes in the top to allow obnoxious gases to escape, I took it down to my shed to let it ferment. Here it is after two weeks brewing.

Tomorrow, I'm going to begin cutting the wood for the box and then I can see if this magic solution works, If it doesn't, I suppose there is always black paint.

Thursday, 16 October 2014

Another Vase

Hi all,

Because my wife is knocking out clay flowers with some rapidity, I decided to make her another vase. This I hoped would keep her quiet for a bit and allow me the pleasure of doing a bit of pyrography on it.

I wanted it to be slender and elegant, so here is what I came up with.

It is essential a prototype because I was experimenting with the scrolled top and having a base to support it.

The centre is a piece of three quarter inch pine and the front and back are both cut from obeche. I cut each piece out and then glued them together like an ice cream wafer. Then I sanded the vase down to smooth out any lumps and bumps. I did the sanding on my oscillating drum sander and it didn't take me long to find my first problem. The curves on the inside of the scrolls were too tight to take even my smallest drum, so I had to do that part by hand. Sanding by hand is a bore so I won't make that mistake again.

Obviously the design also needs a base because it is top heavy, so I designed one in the shape of a flower. I cut it out on the scroll saw, did a bit of shaping with my rotary tool and then did a bit of pyrography on it. I also drilled a hole in the middle to allow me to screw it to the bottom of the vase.

Here it is.

Not to bad even if I say it myself. It didn't need to be a masterpiece because it was only going on a prototype. Anyway, I screwed it on the vase and it looked awful because the bottom of the vase was oblong. It would have looked great on a circular vase but it looked like a right carbuncle on the one I'd just made.

So I made a oblong base that was more suitable and screwed that to the vase and then set about it with my pyrography iron. Even though it is only a prototype I made a right pigs ear of the front,(not shown) so I turned it around and did some more pyrography on the back, which now doubt will now become the front. Here is the finished article.

Not too bad, but it's a case of back to the drawing board because it could have been much better. Here it is with one of my wife's flowers stuck in it.

I am aware that of late my posts have been infrequent, but all of that is about to change. I'm about three quarters of the way through decorating the house but because we are both chocking to death on the paint fumes we are going top knock it on the head till next spring. This and the fact that my latest book, 'The reluctant Pom' is almost finished, means that I will have lots more time for crafty stuff.

My head is full of ideas so I hope to be sharing them with you all soon. They will include inlaying with both wood and clay and I'm also going to have a go at ebonizing. In fact, as I write this post, I've got some ebonizing solution brewing nicely in my shed and I will tell you what that is all about in my next post.

Because my wife is knocking out clay flowers with some rapidity, I decided to make her another vase. This I hoped would keep her quiet for a bit and allow me the pleasure of doing a bit of pyrography on it.

I wanted it to be slender and elegant, so here is what I came up with.

It is essential a prototype because I was experimenting with the scrolled top and having a base to support it.

The centre is a piece of three quarter inch pine and the front and back are both cut from obeche. I cut each piece out and then glued them together like an ice cream wafer. Then I sanded the vase down to smooth out any lumps and bumps. I did the sanding on my oscillating drum sander and it didn't take me long to find my first problem. The curves on the inside of the scrolls were too tight to take even my smallest drum, so I had to do that part by hand. Sanding by hand is a bore so I won't make that mistake again.

Obviously the design also needs a base because it is top heavy, so I designed one in the shape of a flower. I cut it out on the scroll saw, did a bit of shaping with my rotary tool and then did a bit of pyrography on it. I also drilled a hole in the middle to allow me to screw it to the bottom of the vase.

Here it is.

Not to bad even if I say it myself. It didn't need to be a masterpiece because it was only going on a prototype. Anyway, I screwed it on the vase and it looked awful because the bottom of the vase was oblong. It would have looked great on a circular vase but it looked like a right carbuncle on the one I'd just made.

So I made a oblong base that was more suitable and screwed that to the vase and then set about it with my pyrography iron. Even though it is only a prototype I made a right pigs ear of the front,(not shown) so I turned it around and did some more pyrography on the back, which now doubt will now become the front. Here is the finished article.

Not too bad, but it's a case of back to the drawing board because it could have been much better. Here it is with one of my wife's flowers stuck in it.

I am aware that of late my posts have been infrequent, but all of that is about to change. I'm about three quarters of the way through decorating the house but because we are both chocking to death on the paint fumes we are going top knock it on the head till next spring. This and the fact that my latest book, 'The reluctant Pom' is almost finished, means that I will have lots more time for crafty stuff.

My head is full of ideas so I hope to be sharing them with you all soon. They will include inlaying with both wood and clay and I'm also going to have a go at ebonizing. In fact, as I write this post, I've got some ebonizing solution brewing nicely in my shed and I will tell you what that is all about in my next post.

Sunday, 5 October 2014

Wooden Vase

Hi all,

My wife asked me to make a her a wooden vase for some flowers, so I made her one using my scroll saw. The centre is made from maple and the front and back pieces are made from Obeche.

Now you may be thinking that a wooden vase is about as much use as a brolly in a bath, so I'll put you straight before we go any further. My wife has started making flowers out of clay and once she gets going she can be very prolific. The clay flowers are sticking out of every orifice we own and our conservatory is beginning to look like Kew Gardens. Okay, I've exaggerated a bit, but at her request I made a wooden vase for her and here it is.

It stands about five inches high and has holes drilled into the to recess to take the flower stems. I left the front and back plain and cut them from a light coloured wood so that she could do some pyrography work on it when she wanted a break from fiddling with petals.

I am pleased with the shape, which was my own design, and even more pleased with how easy it was to make. I cut out the main piece of maple and then drew around it with a pencil onto a couple of pieces of obeche and then cut them out. All I had to do then was stick the fronts and backs on with some wood glue and drill some holes for the flowers.

My wife was well pleased too and soon began filling it with flowers.

She also did a bit of pyrography work on the front panel. It hasn't been varnished yet, but I think it looks pretty good and displays her flowers nicely.

The only issue I have now is that she is going to want a more making and if I'm going to keep pace with her I will be very busy. In fact, I've already started the next vase and I'll show you that in my next post.

My wife asked me to make a her a wooden vase for some flowers, so I made her one using my scroll saw. The centre is made from maple and the front and back pieces are made from Obeche.

Now you may be thinking that a wooden vase is about as much use as a brolly in a bath, so I'll put you straight before we go any further. My wife has started making flowers out of clay and once she gets going she can be very prolific. The clay flowers are sticking out of every orifice we own and our conservatory is beginning to look like Kew Gardens. Okay, I've exaggerated a bit, but at her request I made a wooden vase for her and here it is.

It stands about five inches high and has holes drilled into the to recess to take the flower stems. I left the front and back plain and cut them from a light coloured wood so that she could do some pyrography work on it when she wanted a break from fiddling with petals.

I am pleased with the shape, which was my own design, and even more pleased with how easy it was to make. I cut out the main piece of maple and then drew around it with a pencil onto a couple of pieces of obeche and then cut them out. All I had to do then was stick the fronts and backs on with some wood glue and drill some holes for the flowers.

My wife was well pleased too and soon began filling it with flowers.

She also did a bit of pyrography work on the front panel. It hasn't been varnished yet, but I think it looks pretty good and displays her flowers nicely.

The only issue I have now is that she is going to want a more making and if I'm going to keep pace with her I will be very busy. In fact, I've already started the next vase and I'll show you that in my next post.

Saturday, 27 September 2014

Intarsia Finished

Hi all, In my last post I left you with a picture of the intarsia project that I was working on. Here it is again just to jog your memory.

At this stage it looked like a kid's jigsaw puzzle, but there was still a lot of work to be done. After cutting the pieces out they had to be shaped to give the fish a realistic look when it is glued together. The shaping was done using various bit of kit in my workshop. A disc and belt sander was used to make sure the back of the pieces were flat and the edges were rounded over with my oscillating drum sander. I also used a rotary tool in places where the drum sander wouldn't go and then stuck the fish together on a backer-board that was cut from a piece of 3mm ply.

The whole thing was then sanded by hand, down to 240 grit and then given three coats of gloss varnish. Finally, I put a hanger on the back and stuck it on the dining room wall for my wife's approval. Here it is complete with a pyrography eye that I forgot to mention.

My wife liked it and asked me to leave it exactly where I'd hung it, so I did and now it stares back at me every morning while I'm eating my toast.

So what are my views on intarsia?

Well,to be honest, they are mixed. I enjoyed shaping the wood and the end result is reasonable, however it is very time consuming. In other words, the amount of effort put in was beyond the amount of pleasure I derived from the finished product. Having said that, I learnt a few things while creating the fish and will use my newly gained knowledge on future project even if they are not intarsia based.

If you fancy doing some intarsia, please have a go. I can recommend the book I used by Kathy Wise, it is informative and well written with clear photos of the processes involved.

For my next project, I will be doing a couple of commissions that came from my wife. I will show you them in my next post. I will have to ask you to be patient because time will be tight. I have just started decorating the living room and I promised a few people that my latest book, 'The Reluctant Pom' would be published buy the end of September. It looks like that might have to slip a few days; still, it's good to be busy.

At this stage it looked like a kid's jigsaw puzzle, but there was still a lot of work to be done. After cutting the pieces out they had to be shaped to give the fish a realistic look when it is glued together. The shaping was done using various bit of kit in my workshop. A disc and belt sander was used to make sure the back of the pieces were flat and the edges were rounded over with my oscillating drum sander. I also used a rotary tool in places where the drum sander wouldn't go and then stuck the fish together on a backer-board that was cut from a piece of 3mm ply.

The whole thing was then sanded by hand, down to 240 grit and then given three coats of gloss varnish. Finally, I put a hanger on the back and stuck it on the dining room wall for my wife's approval. Here it is complete with a pyrography eye that I forgot to mention.

My wife liked it and asked me to leave it exactly where I'd hung it, so I did and now it stares back at me every morning while I'm eating my toast.

So what are my views on intarsia?

Well,to be honest, they are mixed. I enjoyed shaping the wood and the end result is reasonable, however it is very time consuming. In other words, the amount of effort put in was beyond the amount of pleasure I derived from the finished product. Having said that, I learnt a few things while creating the fish and will use my newly gained knowledge on future project even if they are not intarsia based.

If you fancy doing some intarsia, please have a go. I can recommend the book I used by Kathy Wise, it is informative and well written with clear photos of the processes involved.

For my next project, I will be doing a couple of commissions that came from my wife. I will show you them in my next post. I will have to ask you to be patient because time will be tight. I have just started decorating the living room and I promised a few people that my latest book, 'The Reluctant Pom' would be published buy the end of September. It looks like that might have to slip a few days; still, it's good to be busy.

Wednesday, 17 September 2014

The Reluctant Pom

Hi all,

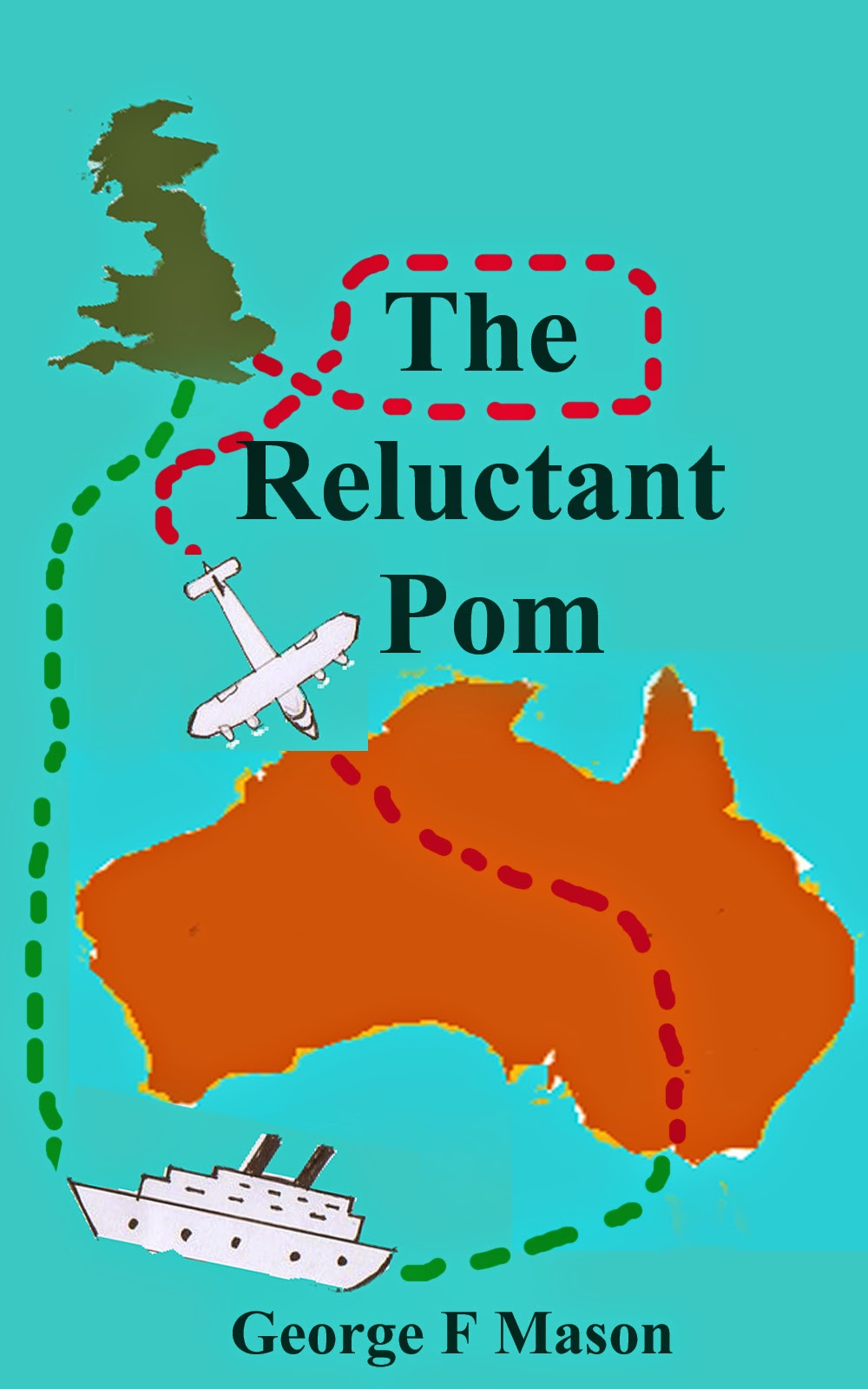

I thought I'd just share with you the cover for my new book 'The Reluctant Pom.' My father dragged me off to Australia when I was an impressionable 16 years old. Having just started work, purchased my first motorbike and discovered girls, moving to the other side of the world was the last thing I wanted to be doing. This book is the follow up to 'A Staffordshire Boy' and is my recollection of the adventure.

Any comments would be welcome. Scroll sawing and pyrography posts will be resumed shortly.

I thought I'd just share with you the cover for my new book 'The Reluctant Pom.' My father dragged me off to Australia when I was an impressionable 16 years old. Having just started work, purchased my first motorbike and discovered girls, moving to the other side of the world was the last thing I wanted to be doing. This book is the follow up to 'A Staffordshire Boy' and is my recollection of the adventure.

Any comments would be welcome. Scroll sawing and pyrography posts will be resumed shortly.

Tuesday, 16 September 2014

Intarsia

Hi all,

In my last post I mention that I was doing some intarsia. Well today I'm going to show you how I'm getting on. But before I rush in, perhaps I ought to explain what intarsia is because until very recently I'd never heard of it either.

According to those who know, intarsia was probably practised in Italy and it is the the name given to pictures made from various pieces of solid wood that are hung on a wall for decoration. To me it seem to be a mixture of, sculpting wood, marquetry and a jigsaw puzzle.

The intarsia process involves sticking a pattern onto one or more pieces of wood and then cutting them out with a scroll saw. Each separate piece is then shaped by sanding and or carving before they a stuck back together. One can use different types of wood and also grain direction to produce effects like those found in marquetry. But other mediums can also be incorporated to good effect, these include pyrography, stains or paints.

I've always fancied having a go at sculpting some wood, and this seem to be the easiest option because it is only two dimensional.

I guess my description of intarsia is about as clear as algebra was to me at school, so it might be better for you google some 'intarsia' images and you will see what it is all about.

So far I have managed to cut out the pieces for a fish of the carp family.

At the moment it looks like child's jigsaw puzzle, but I'm hoping to bring it to life with some delicate sanding and then finish it off with some pyrography. Please watch this space if you want to see how I get on. It will get better, I hope.

By the way, for those interested in my books, my latest offering to the proofreader. It is called 'The Reluctant Pom' and should be available soon. I will give you more details in my next post.

In my last post I mention that I was doing some intarsia. Well today I'm going to show you how I'm getting on. But before I rush in, perhaps I ought to explain what intarsia is because until very recently I'd never heard of it either.

According to those who know, intarsia was probably practised in Italy and it is the the name given to pictures made from various pieces of solid wood that are hung on a wall for decoration. To me it seem to be a mixture of, sculpting wood, marquetry and a jigsaw puzzle.

The intarsia process involves sticking a pattern onto one or more pieces of wood and then cutting them out with a scroll saw. Each separate piece is then shaped by sanding and or carving before they a stuck back together. One can use different types of wood and also grain direction to produce effects like those found in marquetry. But other mediums can also be incorporated to good effect, these include pyrography, stains or paints.

I've always fancied having a go at sculpting some wood, and this seem to be the easiest option because it is only two dimensional.

I guess my description of intarsia is about as clear as algebra was to me at school, so it might be better for you google some 'intarsia' images and you will see what it is all about.

So far I have managed to cut out the pieces for a fish of the carp family.

At the moment it looks like child's jigsaw puzzle, but I'm hoping to bring it to life with some delicate sanding and then finish it off with some pyrography. Please watch this space if you want to see how I get on. It will get better, I hope.

By the way, for those interested in my books, my latest offering to the proofreader. It is called 'The Reluctant Pom' and should be available soon. I will give you more details in my next post.

Thursday, 11 September 2014

Intarsia

Hi all,

Apologies again for the lack of posts, but the house renovation is taking top priority at the moment. I hate the smell of paint so I want to get as much as possible done while the weather is warm enough to have the windows open. This means the intarsia project went to the bottom of the pile.

Talking of paint, what the hell's happened to it? I am using major brands but my experiences are nothing short of terrible. I purchased yellow emulsion and it took four coats to get the walls to the colour on the tin. I could understand if I was trying to cover some black paint but the colour I was painting over was a light shade of pink. Also, the brilliant white gloss I used on my bathroom door has gone yellow after only three months.

The scandalous thing is that I'm paying a fortune for this paint. Does anybody know a brand that doesn't let the side down. I don't mind paying for quality stuff but paint I'm using is a rip off.

That's enough moaning for now, let's get back to the intarsia. I have actually made a start by sticking the pattern onto some wood, so bear with me and in the next couple of days I promise to share my progress with you.

Apologies again for the lack of posts, but the house renovation is taking top priority at the moment. I hate the smell of paint so I want to get as much as possible done while the weather is warm enough to have the windows open. This means the intarsia project went to the bottom of the pile.

Talking of paint, what the hell's happened to it? I am using major brands but my experiences are nothing short of terrible. I purchased yellow emulsion and it took four coats to get the walls to the colour on the tin. I could understand if I was trying to cover some black paint but the colour I was painting over was a light shade of pink. Also, the brilliant white gloss I used on my bathroom door has gone yellow after only three months.

The scandalous thing is that I'm paying a fortune for this paint. Does anybody know a brand that doesn't let the side down. I don't mind paying for quality stuff but paint I'm using is a rip off.

That's enough moaning for now, let's get back to the intarsia. I have actually made a start by sticking the pattern onto some wood, so bear with me and in the next couple of days I promise to share my progress with you.

Tuesday, 26 August 2014

Old Romantic

It was my wife's birthday recently and because she has got most things that she needs, (and quite a few that she doesn't) I decided to make her a trinket box. I cut it out from a piece 20mm thick maple and added a couple of lugs on the back to take the lid.

However, the maple was a bit on the shallow side so I cut out a piece of 6mm mahogany to make it a bit deeper. The bottom, which was cut from a piece of 3mm plywood was then added. As you can see in the photo below I made the box in a rectangular shape to give it clean lines and because of that the lid was easy to cut out. It is made from a hardwood called obeche, which I like because it takes pyrography very well.

In this case, the pyrography that I choose for the lid was a fuchsia, which is one of my wife's favourite flowers. However, it wasn't all plane sailing because I drew it by hand before burning it in with the pyrography and that is when I discovered that I didn't like it. In pyrography terms when that happens it can be an absolute disaster, I did a lot of mutter and almost tossed it in the wheelie, but I managed to retrieve the situation by running the lid over my belt sander. A layer about a sixteenth of an inch was soon removed and I did the pyrography work again.

I was much happier with the second attempt. My wife was pleased when she took the wrapping paper off the box and even happier when she opened the box.

I guess she'd have been even happier if I'd slipped a diamond ring in as well, but you can't have everything.

I think the inside would definitely benefit from a layer of flocking but I ran out of time. Perhaps I will do it one of these days and show it to you again.

Anyway, I've done enough boxes for a bit so I'm going to try my hand at a bit of intarsia work with the scroll saw and pyrography iron. If you haven't come across the term intarsia, don't worry because up until a couple of months ago I hadn't heard of it either. If I've whetted your appetite, please watch out for my next post where all will be revealed

However, the maple was a bit on the shallow side so I cut out a piece of 6mm mahogany to make it a bit deeper. The bottom, which was cut from a piece of 3mm plywood was then added. As you can see in the photo below I made the box in a rectangular shape to give it clean lines and because of that the lid was easy to cut out. It is made from a hardwood called obeche, which I like because it takes pyrography very well.

In this case, the pyrography that I choose for the lid was a fuchsia, which is one of my wife's favourite flowers. However, it wasn't all plane sailing because I drew it by hand before burning it in with the pyrography and that is when I discovered that I didn't like it. In pyrography terms when that happens it can be an absolute disaster, I did a lot of mutter and almost tossed it in the wheelie, but I managed to retrieve the situation by running the lid over my belt sander. A layer about a sixteenth of an inch was soon removed and I did the pyrography work again.

I was much happier with the second attempt. My wife was pleased when she took the wrapping paper off the box and even happier when she opened the box.

I guess she'd have been even happier if I'd slipped a diamond ring in as well, but you can't have everything.

I think the inside would definitely benefit from a layer of flocking but I ran out of time. Perhaps I will do it one of these days and show it to you again.

Anyway, I've done enough boxes for a bit so I'm going to try my hand at a bit of intarsia work with the scroll saw and pyrography iron. If you haven't come across the term intarsia, don't worry because up until a couple of months ago I hadn't heard of it either. If I've whetted your appetite, please watch out for my next post where all will be revealed

Friday, 15 August 2014

Pants Box

Hi all,

In my last post I showed you the latest box that I was working on. Due to pressures of tiling our kitchen it was a while ago, so here is the photo again to jog your memory.

When my wife saw the box she said the shape reminded her of a pair of y fronts and I have to admit that she is right. However, that isn't the only reason I have called it the pants box because the design turned out to be failure. When I cut out the lid and fixed it to the two lugs at the top of the box I found out that it wouldn't open.

With hindsight I should have realised that the top of the box would need to be at least square to allow enough clearance for the lid. Anyway, a box that won't open is about as much use as a concrete float, so I was more than just a tad fed up. To make matters worse, the box was sawn from a plank of maple which is a very hard wood to cut, so after I'd invested time in cutting out the shape I was extremely reluctant to bin it.

The only thing I could do was take the two offending lumps off the top of the box to allow it to open and that is what I did. I then did a drawing of some mushrooms on the lid and burnt them in with my pyrography iron. It was a simple drawing but seeing as the original design had been compromised I didn't want to spend my time doing anything too elaborate on it.

Here is a photo of the box which just needs a coat of flocking on the inside to finish it off.

The lid is cut from a wood called obeche which is a light coloured hardwood that shows up pyrography well.

I am pleased with the box especially the hinge mechanism which, although a bit fiddly to make, works well. I shall use it again in my next box design, but the general shape will be less organic. Hopefully, when the grouting is complete I will find time to share the finished item with you.

In my last post I showed you the latest box that I was working on. Due to pressures of tiling our kitchen it was a while ago, so here is the photo again to jog your memory.

When my wife saw the box she said the shape reminded her of a pair of y fronts and I have to admit that she is right. However, that isn't the only reason I have called it the pants box because the design turned out to be failure. When I cut out the lid and fixed it to the two lugs at the top of the box I found out that it wouldn't open.

With hindsight I should have realised that the top of the box would need to be at least square to allow enough clearance for the lid. Anyway, a box that won't open is about as much use as a concrete float, so I was more than just a tad fed up. To make matters worse, the box was sawn from a plank of maple which is a very hard wood to cut, so after I'd invested time in cutting out the shape I was extremely reluctant to bin it.

The only thing I could do was take the two offending lumps off the top of the box to allow it to open and that is what I did. I then did a drawing of some mushrooms on the lid and burnt them in with my pyrography iron. It was a simple drawing but seeing as the original design had been compromised I didn't want to spend my time doing anything too elaborate on it.

Here is a photo of the box which just needs a coat of flocking on the inside to finish it off.

The lid is cut from a wood called obeche which is a light coloured hardwood that shows up pyrography well.

I am pleased with the box especially the hinge mechanism which, although a bit fiddly to make, works well. I shall use it again in my next box design, but the general shape will be less organic. Hopefully, when the grouting is complete I will find time to share the finished item with you.

Monday, 4 August 2014

Easy Boxes

Hi all, sorry that it's been a while between posts. I guess it will carry on being that way until this house renovation is over, so please bear with me.

In between knocking off the tiles in the kitchen and re-plastering the walls where they came from I have found, what seemed like a few nano seconds of time to do a little bit of craft work. I managed to finish making another of those small square boxes and even did a little bit of pyrography on the lid.

I sometimes get a little stuck when it comes to choosing what to decorate the top of a box with and this was no exception. In the end, I drew a heart shape and then just did a bit of a doodle pattern around it. I didn't bother pencilling it it first, I just let my instinct take over with the pyrography iron and tried to keep the design as symmetrical as possible. The thing with doodles is that you know each one is unique. This is the only box like this one and it will always be a one off.

I haven't made my mind up yet, but I might sell it on folksy to see if anybody else likes it. Usually, when I finish a box my wife bagsies it, but she didn't seem so keen to snaffle this one up, so perhaps it's not to her taste. If anybody has any view or constructive criticism I'd be pleased to hear any comments.

Anyway, beside the square box I have started working on another of a totally different shape. My aim is to find a way to make boxes with lids that are easy to make. Not because I'm bone idle, but because it will allow me to spend more time on the decoration, be it either scroll work, pyrography or both.

The box above I am hoping will go someway towards achieving my goal. It is cut from a single piece of maple and the inside contours match the drum of my spindle sander. The two lugs at the top will take the hinges that will be pinned, just like those on the square box.

It is too early to say if it will be a success, but I will let you know in my next post.

In between knocking off the tiles in the kitchen and re-plastering the walls where they came from I have found, what seemed like a few nano seconds of time to do a little bit of craft work. I managed to finish making another of those small square boxes and even did a little bit of pyrography on the lid.

I sometimes get a little stuck when it comes to choosing what to decorate the top of a box with and this was no exception. In the end, I drew a heart shape and then just did a bit of a doodle pattern around it. I didn't bother pencilling it it first, I just let my instinct take over with the pyrography iron and tried to keep the design as symmetrical as possible. The thing with doodles is that you know each one is unique. This is the only box like this one and it will always be a one off.

I haven't made my mind up yet, but I might sell it on folksy to see if anybody else likes it. Usually, when I finish a box my wife bagsies it, but she didn't seem so keen to snaffle this one up, so perhaps it's not to her taste. If anybody has any view or constructive criticism I'd be pleased to hear any comments.

Anyway, beside the square box I have started working on another of a totally different shape. My aim is to find a way to make boxes with lids that are easy to make. Not because I'm bone idle, but because it will allow me to spend more time on the decoration, be it either scroll work, pyrography or both.

The box above I am hoping will go someway towards achieving my goal. It is cut from a single piece of maple and the inside contours match the drum of my spindle sander. The two lugs at the top will take the hinges that will be pinned, just like those on the square box.

It is too early to say if it will be a success, but I will let you know in my next post.

Sunday, 20 July 2014

Poppy

Hi all,

Sorry it's been a while since my last post but I've been very busy on the house restoration. So far I've done the dining room, the bathroom and my mother-in law's room. I have also done the front and back gardens whilst the weather has been nice.

So, I only have our bedroom, inner hall, the living room, the utility room, the conservatory and the kitchen to complete before Christmas.

The kitchen is the biggest job, not least because the people who lived here before us wall papered over wall paper and I've had to get 5 layers off. It was stuck like a tic to a terrier and took most of the week to get it off. I tried a steamer once in a bathroom a couple of houses ago. All was going well, the paper came off a treat but unfortunately so did the plaster, a barrow load fell off the wall into my bath with a resounding crash. That was when me and steamers got a divorce.

However, that wasn't the worst of it. When I took took some paper off by the wall units this is what I found. I wondered why there was a bulge in the paper.

If you are wondering what it is I will tell you. It's the hole where the boiler used to be. When they decommission the boiler they stuck the lid off a biscuit tin in the hole and cemented it in with some rubber glue. If it had been completely covered by the wall units I could have forgiven them, but to put the wall cupboards half over it and paper over the mess is absolutely ridiculous and shame on the workman who did it. I know where I'd like to stick the tube of rubber glue.

Anyway, that's enough of that. I did manage to do a bit of scroll sawing and pyrography and combined the two on a practice piece. I had always fancied inlaying one wood into another and thought I'd give it a go. In my first attempt I used mahogany for the dark wood and tulip wood for the lighter wood to give it contrast.

The technique of inlaying two woods is simple. You wrap Sellotape around the two pieces of wood, with the lightest on the top, and cut the pattern out. When you take the Sellotape off, the centre of the dark wood can be discarded and the lighter wood from the top layer takes its place.

The only difficulty comes in judging the angle of the cut. Let me explain. If you do a straight forward cut with no angle at all, you will find that you have a gap around the inlay that is the width of your saw blade, which is undesirable. So you need to do the cutting at an angle so that the top piece slides neatly into the piece below with no gap. The tricky bit is finding the right angle because it depends on the thickness of the wood that you are cutting.

Anyway, when I cut out the letter "T" on my scroll saw, I used an angle of 1.5 degrees, and as the wood I was cutting was 6mm thick it was almost perfect but just a little tight. So, I made an adjustment of half a degree and cut out a poppy only to find that I'd made the adjustment the wrong way. The net result was a less than perfect fitting inlay. Still we all learn by our mistakes. I went on to do the pyrography work on the poppy and I'm pleased with how it came out. The next one should be much better.

The thing is, it must have looked quite good to my wife because she soon snaffled it and stuck it on the front of a box of candles that were desperately in need of cheering up.

I am working on the design for my next scroll saw and pyrography project and hope to show you it in my next post.

Sorry it's been a while since my last post but I've been very busy on the house restoration. So far I've done the dining room, the bathroom and my mother-in law's room. I have also done the front and back gardens whilst the weather has been nice.

So, I only have our bedroom, inner hall, the living room, the utility room, the conservatory and the kitchen to complete before Christmas.

The kitchen is the biggest job, not least because the people who lived here before us wall papered over wall paper and I've had to get 5 layers off. It was stuck like a tic to a terrier and took most of the week to get it off. I tried a steamer once in a bathroom a couple of houses ago. All was going well, the paper came off a treat but unfortunately so did the plaster, a barrow load fell off the wall into my bath with a resounding crash. That was when me and steamers got a divorce.

However, that wasn't the worst of it. When I took took some paper off by the wall units this is what I found. I wondered why there was a bulge in the paper.

If you are wondering what it is I will tell you. It's the hole where the boiler used to be. When they decommission the boiler they stuck the lid off a biscuit tin in the hole and cemented it in with some rubber glue. If it had been completely covered by the wall units I could have forgiven them, but to put the wall cupboards half over it and paper over the mess is absolutely ridiculous and shame on the workman who did it. I know where I'd like to stick the tube of rubber glue.

Anyway, that's enough of that. I did manage to do a bit of scroll sawing and pyrography and combined the two on a practice piece. I had always fancied inlaying one wood into another and thought I'd give it a go. In my first attempt I used mahogany for the dark wood and tulip wood for the lighter wood to give it contrast.